Your current location:Home > Products > Liquid Dessicant Air Conditioner

Overview

Low humidity air desiccant unit is an air handling equipment with solution (lithium bromide, lithium chloride, calcium chloride, etc.) as working fluid. The unit is driven by heat pump and adopts advanced solution dehumidification technology. Release moisture to realize the regulation of air temperature and humidity. It is a dehumidification equipment integrating cold and heat source, dehumidification section, regeneration section, filter section, air supply section and exhaust section. It takes full advantage of the highly efficient hygroscopic properties of the solution, and can treat the air moisture content as low as 2.1g/kg. It is suitable for occasions with low humidity requirements such as battery packaging workshop and high-definition printing workshop.

Advantages

1. Energy saving and environment protection

● The working temperature of the dehumidification section is 10-20℃, which avoids energy waste caused by reheating when the dehumidification temperature is too low, and improves the cooling capacity of the heat pump without the problem of frost in conventional dehumidifiers.

● Dehumidification cooling and solution regeneration are driven by heat pump, and more than 90% of condensation heat is recycled, which greatly improves the cooling efficiency of the system, and does not discharge waste heat to the surrounding.

2. Strong dehumidification ability and wide application range

● The air can be cooled and dehumidified or heated to dehumidify, with a minimum of 2.1g/kg.

3. Improve indoor air quality

● High-concentration salt solution can kill most bacteria, viruses and other molds, and the killing rate can reach more than 99%, which provides a favorable defense weapon against airborne diseases such as influenza and coronavirus.

● Constant temperature and humidity, humidity deviation ±1%.

4. Stable performance

● The salt solution does not decompose or volatilize, the moisture absorption and regeneration efficiency are stable, and it is less affected by the changes of fresh air and return air parameters, the dehumidification performance is not attenuated, and the service life is long.

Features

1. The counter-flow air supply design has high gas-liquid heat exchange efficiency. Compared with the cross-flow air supply design, the volume is more compact, and the equipment occupies a smaller area of the equipment room.

2. The super absorbent core is made of polymer fiber material through a series of processes such as compression molding, high temperature carbonization, bonding, curing, etc. It has the advantages of anti-aging, corrosion resistance, mildew resistance, and long service life.

3. Combined with the design of counter-flow air supply, it can effectively solve the common liquid-carrying problem in cross-flow air supply.

4. Advanced solution concentration control technology, the unit has stronger and more accurate dehumidification capability, and the minimum fresh air humidity can be controlled at 2.1g/kg.

5. International standard, reliable operation

● The solution tank is integrally formed, and there is no hidden danger of air leakage and liquid leakage.

● The heat exchanger is made of titanium tube, which will never rust.

● Refrigeration components, controller components, water pumps, fans and other main components are of international famous brands, which are stable and reliable.

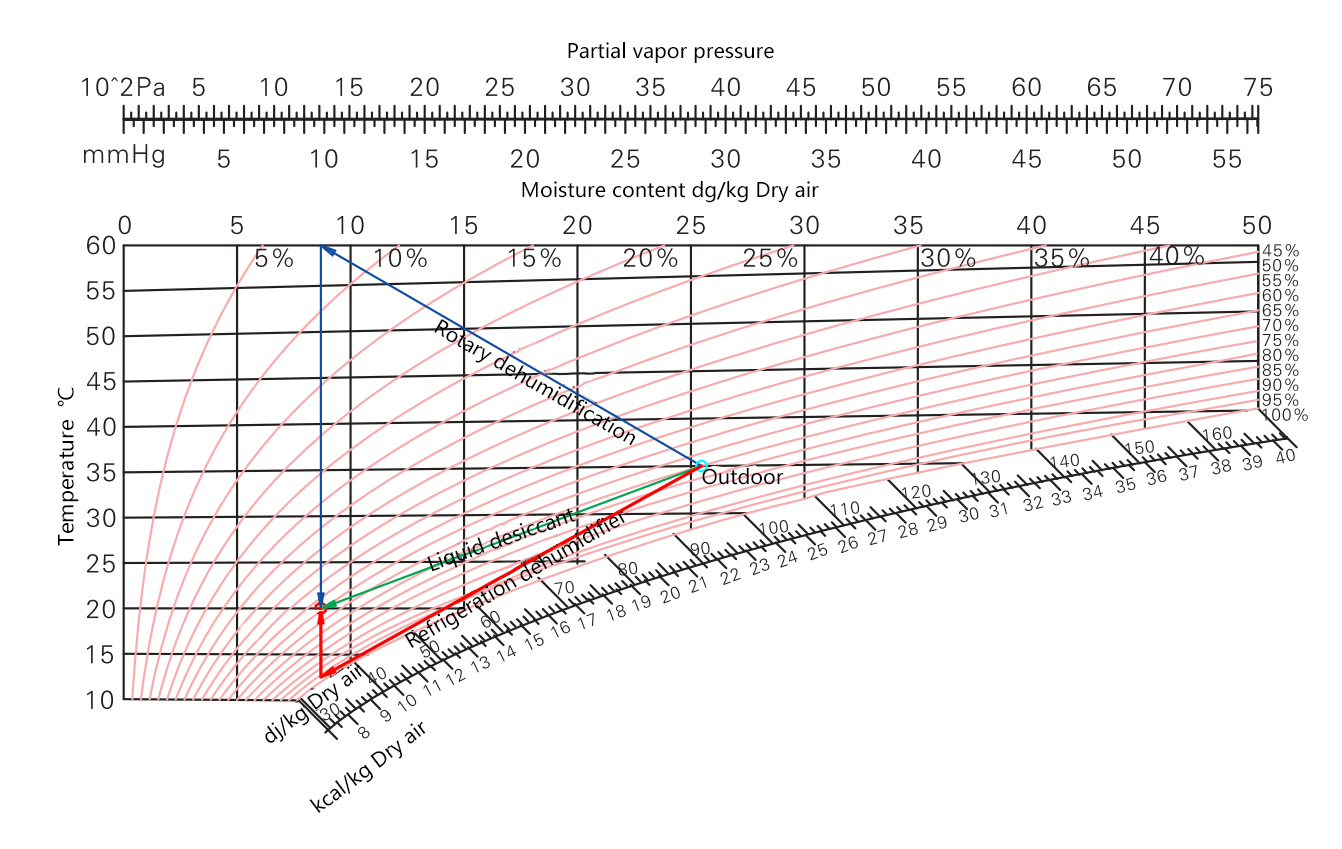

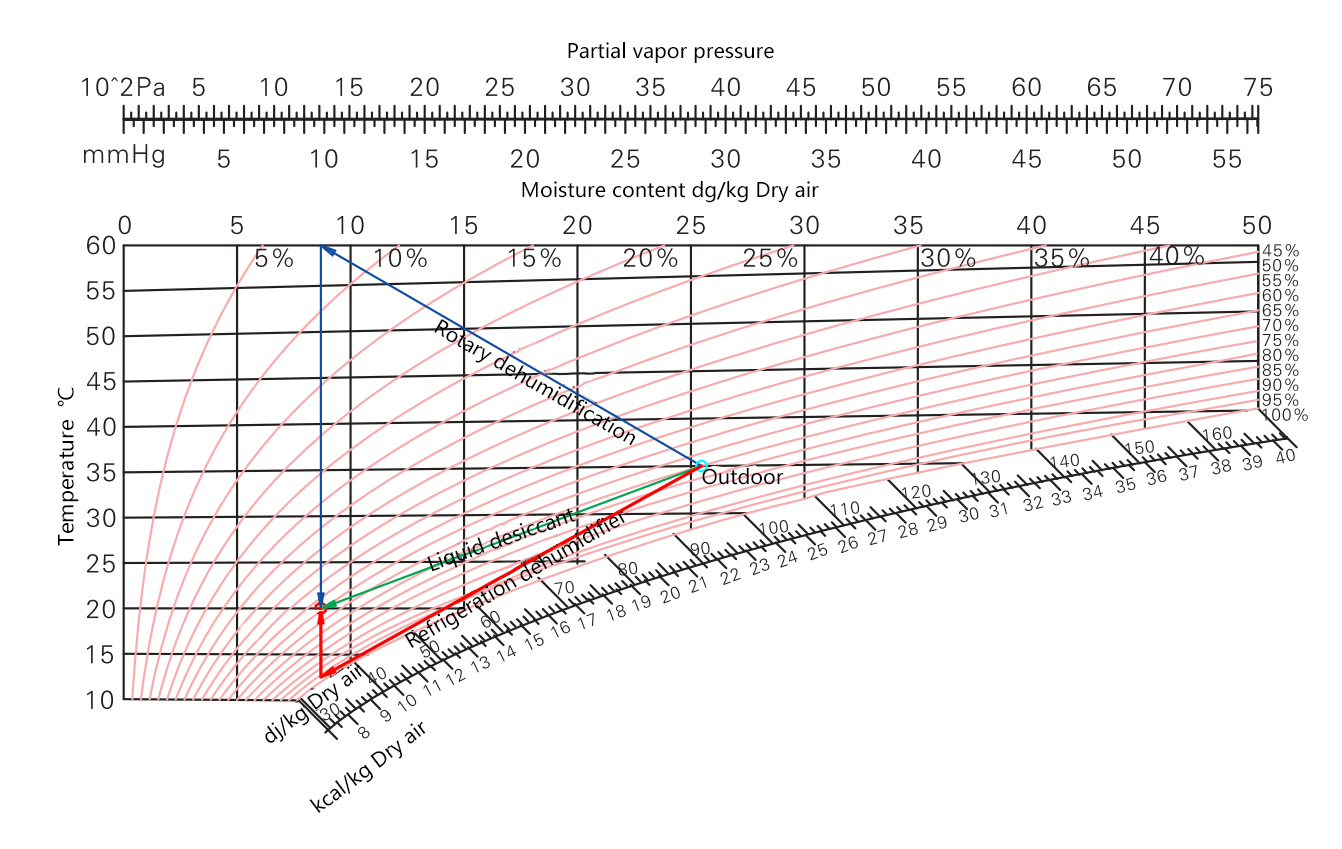

Working Principle

Application

Painting factory, steel wire tire workshop, battery packaging workshop, high-definition color printing factory, chemical laboratory, etc.

Specification

| Model ( N□□) | 03B | 06B | 09B | 12B | 15B |

| Power Form | 3PH-380V-50Hz | ||||

| Optimum Airflow (m³/h) | 1000 | 2000 | 3000 | 4000 | 5000 |

| Max Regenerative Airflow (m³/h) | 1200 | 2400 | 3600 | 4800 | 6000 |

| Cooling Capacity (kW) | 7.2 | 14.4 | 21.6 | 28.8 | 36 |

| Dehumidify Capacity (kg/h) | 5.4 | 10.8 | 16.2 | 21.6 | 27 |

| Noise (dB(A)) | 60 | 61 | 62 | 63 | 64 |

| Refrigeration System | |||||

| Coolant System | R407C | ||||

| Type of Supply and Exhaust Fan | Outer rotor centrifugal motor | ||||

| Filtration Class | Primary (G4) | ||||

| Air Supply Pressure (Pa) | 130 | 280 | 300 | 330 | 350 |

| Exhaust Pressure (Pa) | 130 | 240 | 250 | 260 | 270 |

| Reference Weight (kg) | 660 | 1050 | 1600 | 1850 | 2200 |

Note:

1. Nominal fresh air condition: dry bulb temperature 36°C, relative humidity 65%; nominal return air condition: dry bulb temperature 26°C, relative humidity 40%.

2. Nominal air supply conditions: dry bulb temperature 16°C, relative humidity 35%.

3. Please contact our company for different working conditions.

4. City tap water can be used as supplementary water source without softening.

5. The fan of the unit can be specially adapted or configured with a frequency converter according to the customer's residual pressure requirements.

6. For non-standard units, please call our company for consultation.

Project Cases

Overview

Low humidity air desiccant unit is an air handling equipment with solution (lithium bromide, lithium chloride, calcium chloride, etc.) as working fluid. The unit is driven by heat pump and adopts advanced solution dehumidification technology. Release moisture to realize the regulation of air temperature and humidity. It is a dehumidification equipment integrating cold and heat source, dehumidification section, regeneration section, filter section, air supply section and exhaust section. It takes full advantage of the highly efficient hygroscopic properties of the solution, and can treat the air moisture content as low as 2.1g/kg. It is suitable for occasions with low humidity requirements such as battery packaging workshop and high-definition printing workshop.

Advantages

1. Energy saving and environment protection

● The working temperature of the dehumidification section is 10-20℃, which avoids energy waste caused by reheating when the dehumidification temperature is too low, and improves the cooling capacity of the heat pump without the problem of frost in conventional dehumidifiers.

● Dehumidification cooling and solution regeneration are driven by heat pump, and more than 90% of condensation heat is recycled, which greatly improves the cooling efficiency of the system, and does not discharge waste heat to the surrounding.

2. Strong dehumidification ability and wide application range

● The air can be cooled and dehumidified or heated to dehumidify, with a minimum of 2.1g/kg.

3. Improve indoor air quality

● High-concentration salt solution can kill most bacteria, viruses and other molds, and the killing rate can reach more than 99%, which provides a favorable defense weapon against airborne diseases such as influenza and coronavirus.

● Constant temperature and humidity, humidity deviation ±1%.

4. Stable performance

● The salt solution does not decompose or volatilize, the moisture absorption and regeneration efficiency are stable, and it is less affected by the changes of fresh air and return air parameters, the dehumidification performance is not attenuated, and the service life is long.

Features

1. The counter-flow air supply design has high gas-liquid heat exchange efficiency. Compared with the cross-flow air supply design, the volume is more compact, and the equipment occupies a smaller area of the equipment room.

2. The super absorbent core is made of polymer fiber material through a series of processes such as compression molding, high temperature carbonization, bonding, curing, etc. It has the advantages of anti-aging, corrosion resistance, mildew resistance, and long service life.

3. Combined with the design of counter-flow air supply, it can effectively solve the common liquid-carrying problem in cross-flow air supply.

4. Advanced solution concentration control technology, the unit has stronger and more accurate dehumidification capability, and the minimum fresh air humidity can be controlled at 2.1g/kg.

5. International standard, reliable operation

● The solution tank is integrally formed, and there is no hidden danger of air leakage and liquid leakage.

● The heat exchanger is made of titanium tube, which will never rust.

● Refrigeration components, controller components, water pumps, fans and other main components are of international famous brands, which are stable and reliable.

Working Principle

Application

Painting factory, steel wire tire workshop, battery packaging workshop, high-definition color printing factory, chemical laboratory, etc.

Specification

| Model ( N□□) | 03B | 06B | 09B | 12B | 15B |

| Power Form | 3PH-380V-50Hz | ||||

| Optimum Airflow (m³/h) | 1000 | 2000 | 3000 | 4000 | 5000 |

| Max Regenerative Airflow (m³/h) | 1200 | 2400 | 3600 | 4800 | 6000 |

| Cooling Capacity (kW) | 7.2 | 14.4 | 21.6 | 28.8 | 36 |

| Dehumidify Capacity (kg/h) | 5.4 | 10.8 | 16.2 | 21.6 | 27 |

| Noise (dB(A)) | 60 | 61 | 62 | 63 | 64 |

| Refrigeration System | |||||

| Coolant System | R407C | ||||

| Type of Supply and Exhaust Fan | Outer rotor centrifugal motor | ||||

| Filtration Class | Primary (G4) | ||||

| Air Supply Pressure (Pa) | 130 | 280 | 300 | 330 | 350 |

| Exhaust Pressure (Pa) | 130 | 240 | 250 | 260 | 270 |

| Reference Weight (kg) | 660 | 1050 | 1600 | 1850 | 2200 |

Note:

1. Nominal fresh air condition: dry bulb temperature 36°C, relative humidity 65%; nominal return air condition: dry bulb temperature 26°C, relative humidity 40%.

2. Nominal air supply conditions: dry bulb temperature 16°C, relative humidity 35%.

3. Please contact our company for different working conditions.

4. City tap water can be used as supplementary water source without softening.

5. The fan of the unit can be specially adapted or configured with a frequency converter according to the customer's residual pressure requirements.

6. For non-standard units, please call our company for consultation.

Project Cases