Your current location:Home > Products > Evaporative Cooling Air Handling Unit

Overview

This product integrates multiple key technologies such as indirect evaporation, frequency conversion refrigeration, three-dimensional uniform water distribution, real-time water quality detection and processing, and intelligent group control. It adopts modular design and has the characteristics of high efficiency and energy saving, stable operation, anti-freezing and low noise. It can be used as a The independent cooling solution for new and old projects of the data center can also be used as a supplementary solution for the mechanical cooling of the data center, and the energy saving effect is very obvious. It is also suitable for energy saving and consumption reduction in various computer rooms and power distribution rooms.

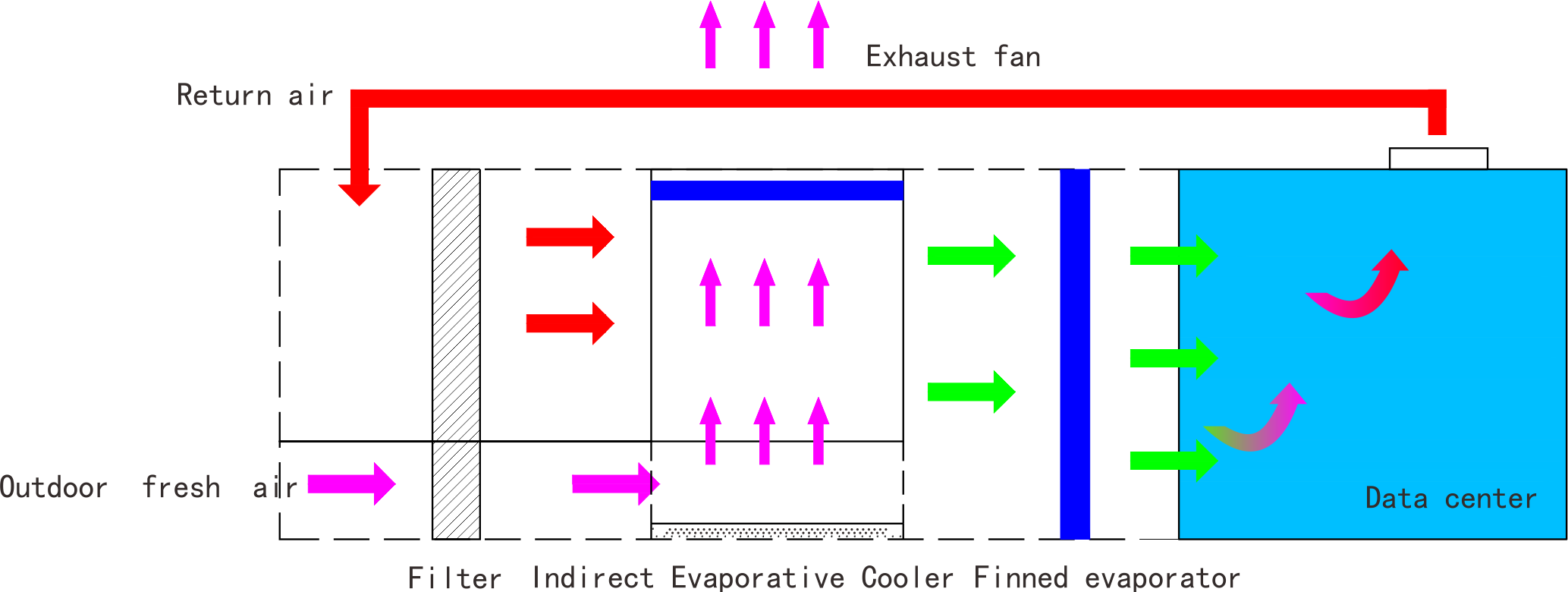

Working Principle

Features

1. The inner frame structure has good air tightness and prevents cold bridges.

● High-pressure polyurethane insulation layer is used in the middle of the double-layer panel, and the thermal conductivity is less than 0.0195W/m2℃.

● The full panel is detachable, and there is a maintenance platform, which is convenient and simple to maintain.

● Segment (layer) structure design, no need for super high transportation, can be assembled on site to improve the quality of the whole machine.

2. The water system adopts double descaling, sterilization and purification treatment to ensure stable operation and long life of the unit.

3. The core body adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of ambient temperature and humidity, automatic control of fan speed, the unit has functions such as filter dirty block alarm, automatic fan acceleration and long-life rotation.

5. The unit can adopt three intelligent and efficient operation modes of dry working condition, wet working condition and composite working condition; it can also choose energy-saving mode, water-saving mode, economical mode and dehumidification mode to operate according to actual needs.

6. The unit reserves energy consumption collection interface, which can collect power consumption data in real time.

7. The indirect evaporative cooling core is made of high hydrophilic polymer material by special process, and adopts a wide-pitch plate structure, which is not deformed by high pressure difference, high heat exchange efficiency, corrosion resistance and long life, and self-cleaning Function.

8. Large-aperture three-dimensional water distribution, uniform water distribution, not easy to block, can be cleaned; flexible and precise water spraying, to prevent floating water leakage.

9. The unit adopts high-efficiency components from internationally renowned brands, and both the compressor and EC fan are variable frequency.

10. The unit adopts a power distribution structure in which the compressor supplies power alone, (fan + water pump) uses two circuits of electricity (at least one of which is U power), and two circuits of electricity are used for control (at least one of which is U power) to ensure the safety of data center electricity consumption. .

11. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, high and low voltage, overload, differential pressure, antifreeze, and abnormal liquid level.

Specification

| Model | ASK-J600 | ASK-J800 |

| Max Airflows (m³/h) | 60000 | 80000 |

| Supply/Return Air Emperature (℃) | 25/38 | 25/38 |

| Max Power (kW) | 30 | 40 |

| Max Residual Pressure (Pa) | 250 | 250 |

| Max mechanical supplemental cooling capacity | 80% | 80% |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases

Overview

This product integrates multiple key technologies such as indirect evaporation, frequency conversion refrigeration, three-dimensional uniform water distribution, real-time water quality detection and processing, and intelligent group control. It adopts modular design and has the characteristics of high efficiency and energy saving, stable operation, anti-freezing and low noise. It can be used as a The independent cooling solution for new and old projects of the data center can also be used as a supplementary solution for the mechanical cooling of the data center, and the energy saving effect is very obvious. It is also suitable for energy saving and consumption reduction in various computer rooms and power distribution rooms.

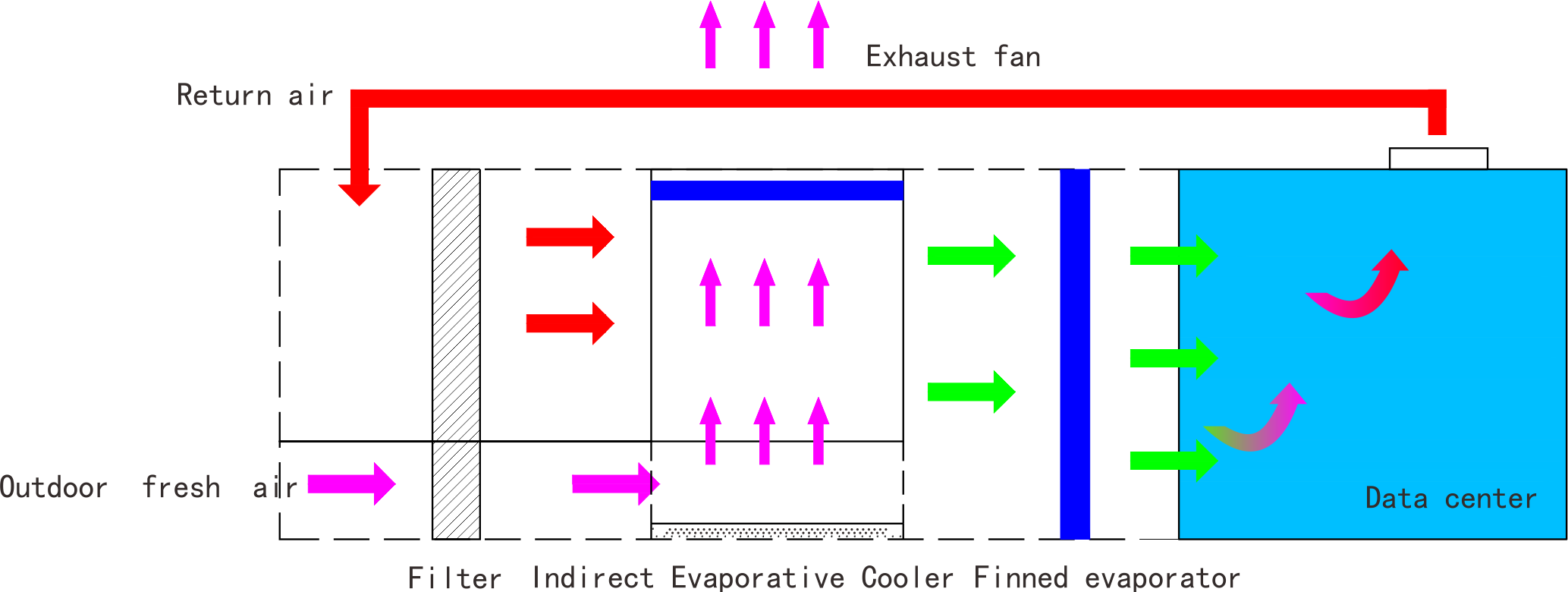

Working Principle

Features

1. The inner frame structure has good air tightness and prevents cold bridges.

● High-pressure polyurethane insulation layer is used in the middle of the double-layer panel, and the thermal conductivity is less than 0.0195W/m2℃.

● The full panel is detachable, and there is a maintenance platform, which is convenient and simple to maintain.

● Segment (layer) structure design, no need for super high transportation, can be assembled on site to improve the quality of the whole machine.

2. The water system adopts double descaling, sterilization and purification treatment to ensure stable operation and long life of the unit.

3. The core body adopts a new structure design, which can be quickly disassembled and replaced, effectively reducing the maintenance cost in the later period.

4. The whole machine adopts PLC and touch screen intelligent control, providing a variety of interface types. Real-time detection of ambient temperature and humidity, automatic control of fan speed, the unit has functions such as filter dirty block alarm, automatic fan acceleration and long-life rotation.

5. The unit can adopt three intelligent and efficient operation modes of dry working condition, wet working condition and composite working condition; it can also choose energy-saving mode, water-saving mode, economical mode and dehumidification mode to operate according to actual needs.

6. The unit reserves energy consumption collection interface, which can collect power consumption data in real time.

7. The indirect evaporative cooling core is made of high hydrophilic polymer material by special process, and adopts a wide-pitch plate structure, which is not deformed by high pressure difference, high heat exchange efficiency, corrosion resistance and long life, and self-cleaning Function.

8. Large-aperture three-dimensional water distribution, uniform water distribution, not easy to block, can be cleaned; flexible and precise water spraying, to prevent floating water leakage.

9. The unit adopts high-efficiency components from internationally renowned brands, and both the compressor and EC fan are variable frequency.

10. The unit adopts a power distribution structure in which the compressor supplies power alone, (fan + water pump) uses two circuits of electricity (at least one of which is U power), and two circuits of electricity are used for control (at least one of which is U power) to ensure the safety of data center electricity consumption. .

11. The unit has complete protection functions, providing alarm functions such as power phase loss, undervoltage, high and low voltage, overload, differential pressure, antifreeze, and abnormal liquid level.

Specification

| Model | ASK-J600 | ASK-J800 |

| Max Airflows (m³/h) | 60000 | 80000 |

| Supply/Return Air Emperature (℃) | 25/38 | 25/38 |

| Max Power (kW) | 30 | 40 |

| Max Residual Pressure (Pa) | 250 | 250 |

| Max mechanical supplemental cooling capacity | 80% | 80% |

For specific performance parameters, dimensions and use of non-standard working conditions, please contact the company's technical department.

Project Cases