Your current location:Home > Project > Industrial Cooling

Rubber Company Vulcanization Workshop Ventilation and Cooling Project

Project Overview

Located in Zhejiang Province, this project focuses on rubber product and automotive tire manufacturing, with core equipment installed in the vulcanization workshop. The workshop houses 9 vulcanization production lines, where operators work on both sides of the vulcanizing equipment at fixed workstations. Characterized by persistent high temperatures, the workshop can reach 40–50°C under extreme conditions, accompanied by strong odors and severe air stagnation, exposing workers to a harsh, polluted environment. Traditional compression refrigeration air conditioners struggle with low cooling efficiency, high energy consumption, and substantial maintenance costs. In contrast, evaporative cooling technology excels at managing complex heat loads, enabling significant energy savings and efficient environmental control, making it the optimal solution for improving working conditions.

Operational Configuration

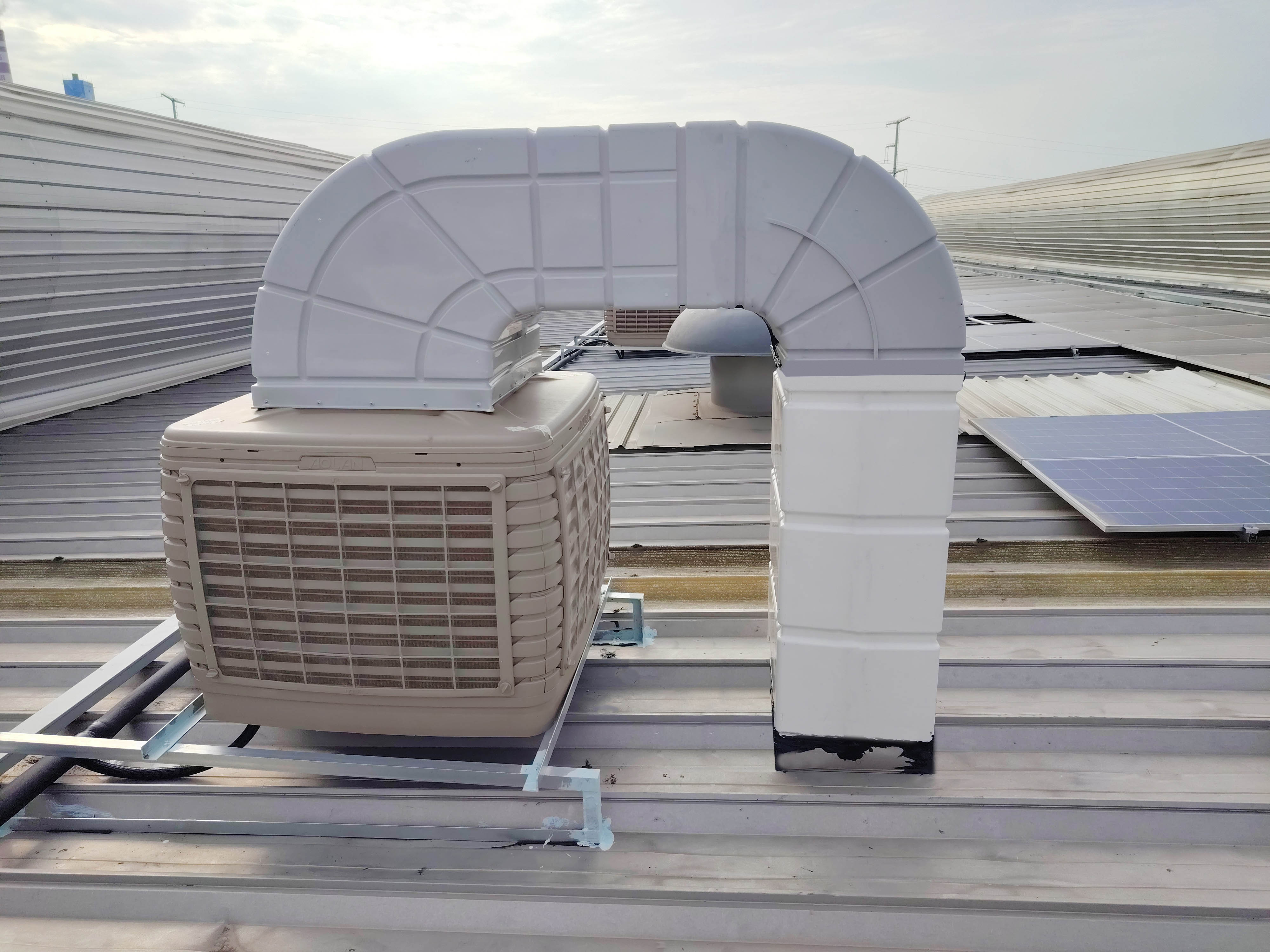

The design integrates 90 Aolan multi-series evaporative air coolers, adopting a precise spot-cooling mode. These air coolers are evenly installed on the roof, with air ducts laid along the factory building at a height of approximately 3 meters from the ground. Each duct section is equipped with dual outlets for directional air supply. For the 9 vulcanization production lines, every two lines are grouped and centrally controlled by dedicated air coolers. The corresponding control panels are integrated to enable efficient and convenient intelligent management and regulation.

Performance Highlights

The system integrates workplace fresh air supply, cooling, and efficient ventilation functions. It ensures uninterrupted operational efficiency of production lines while effectively tackling high temperatures and odors in the workshop, significantly enhancing the working environment quality. By creating a comfortable production space for employees, it strongly drives productivity improvement. Since its commissioning in 2024, the equipment has demonstrated stable and reliable operation with outstanding performance, successfully overcoming the constraints of traditional high-temperature environments. The temperature in the workshop operational zone has been drastically reduced from over 40°C previously to a comfortable supply air temperature of around 29°C, marking a qualitative leap in environmental control.