Your current location:Home > Project > Industrial Cooling

Ventilation and Cooling Project for New Material Production Workshop

Ventilation and Cooling Project for New Material Production Workshop

Project Overview

This project targets a production workshop for 3D perforated nonwoven fabric and hot-air nonwoven fabric, housed in a closed cleanroom environment. Due to heat generated by operational equipment and inadequate ventilation, the workshop suffers from persistently high temperatures. Traditional compressor-based cooling systems are prone to clogging from raw material debris, resulting in poor cooling efficiency, high energy consumption, and elevated maintenance costs. In contrast, evaporative cooling technology effectively addresses complex heat load challenges, achieving efficient temperature reduction while significantly lowering energy consumption, making it the ideal solution.

Operational Design

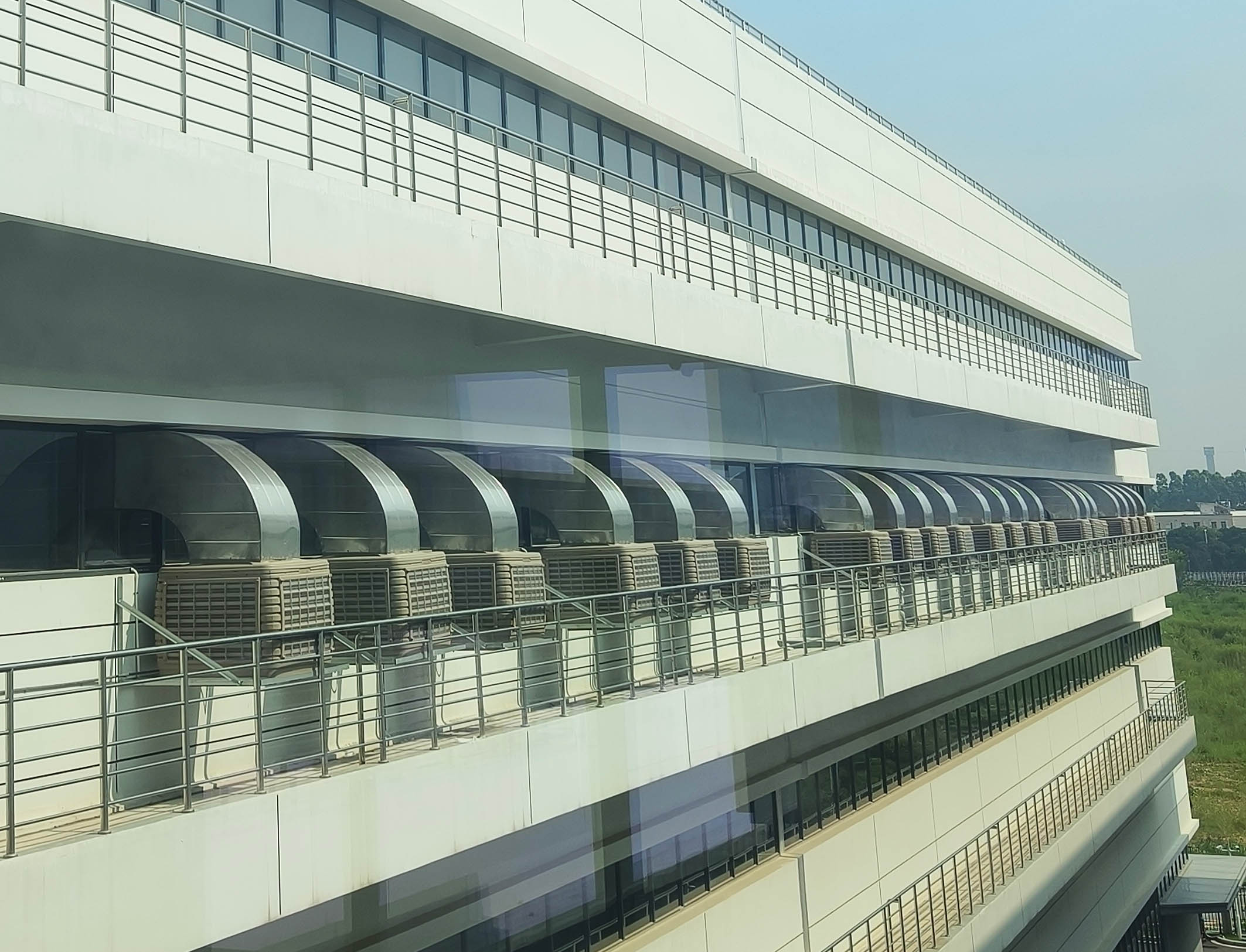

The design incorporates 57 Aolan Fengchi-series evaporative air coolers installed across the 1st to 5th floors of the production workshop. Based on the distribution of production equipment and the specific needs of employee workstations, each unit employs direct airflow cooling to ensure precise coverage of all operational areas and equipment zones. This optimized approach enables effective temperature control, ensuring a comfortable and stable production environment, thereby enhancing operational efficiency and achieving targeted cooling outcomes.

Performance Highlights

The project features a sealed workshop design, with operational settings tailored to seasonal variations: evaporative cooling in wet mode during spring, summer, and autumn, and shutdowns in winter. Since its 2024 launch, after thorough commissioning and fine-tuning, the system has maintained stable operation and delivered outstanding results. Measured data confirms that the air coolers' outlet temperatures consistently stay within 29–30°C, while the working zones experience an 8–10°C drop. These outcomes fully meet project expectations, showcasing remarkable energy efficiency.