Your current location:Home > Project > Data Center Cooling

Qinghai Telecom Dashizi Computer Room Renovation Project

Project Overview

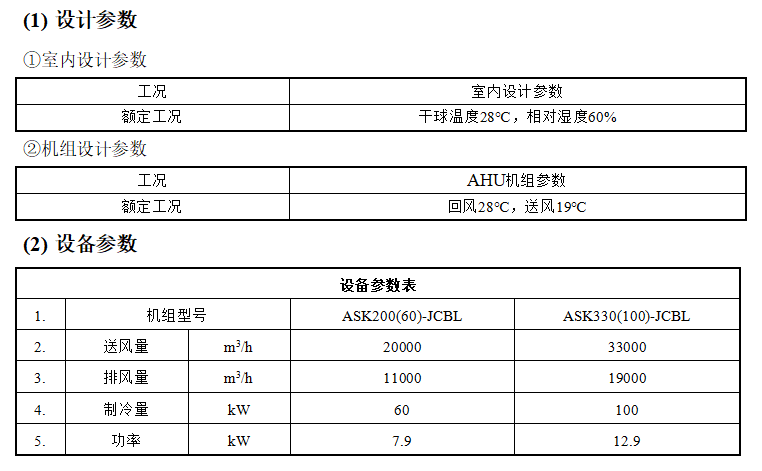

This project is a large cooling equipment room of Qinghai Telecom. The design uses two Aolan indirect evaporative cooling units, models ASK200(60)-JCBL and ASK330(100)-JCBL. This project carries out personalized energy-saving renovation of the computer room, mainly to improve the energy efficiency of the original air conditioning system in the computer room and solve the problem of low energy saving rate. According to the actual situation of the project, a wet film cooling device was added to the air inlet surface of the outdoor condenser of the original three air-cooled air conditioners in the computer room to reduce the inlet air temperature of the condenser, thus improving the overall performance of the air-cooled air conditioner. The indirect evaporative cooling tower group adopts split type and is installed with independent exhaust section. The wind passes through the outdoor fresh air in the dry channel and wet channel of the core body for heat exchange and breathing. At the same time, diversion and disturbance air supply are set up to increase end disturbance and balance the temperature in multiple indoor areas.

Operating mode

This project uses a deep evaporative cooling structural group combined with the original precision air conditioning of the computer room. The deep evaporative cooling structural group is operated in the low-temperature winter and transition seasons, and the original precision air-conditioning system is operated in the high-temperature and high-humidity summer; making full use of the full capacity of the northwest region The heat dissipation cooling fan group operates in dry mode and wet mode. The original precision air conditioner operates in mechanical refrigeration mode and automatically switches by sensing the indoor and outdoor temperature and humidity conditions through indoor and outdoor temperature and humidity sensors.

Effect display

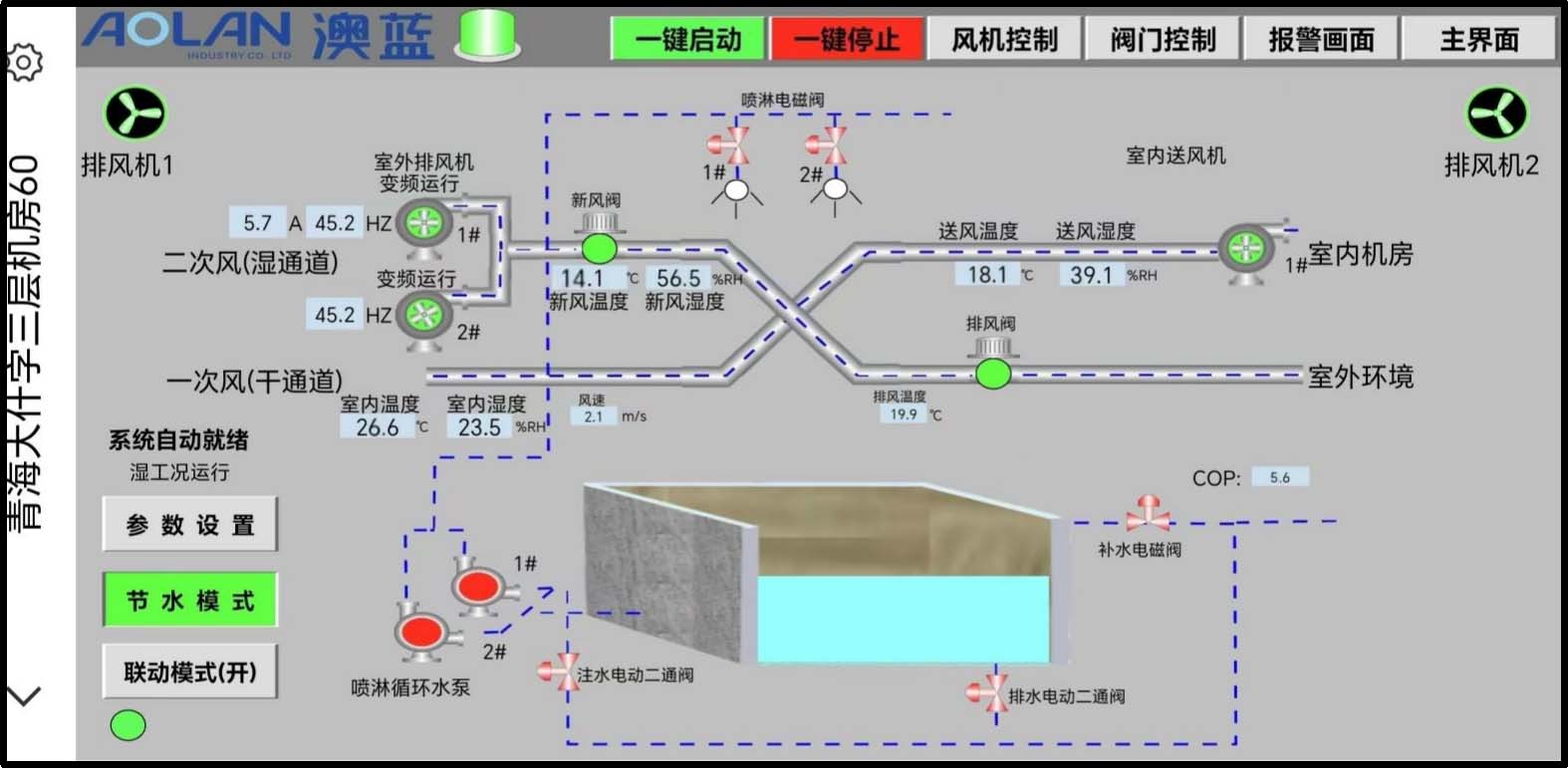

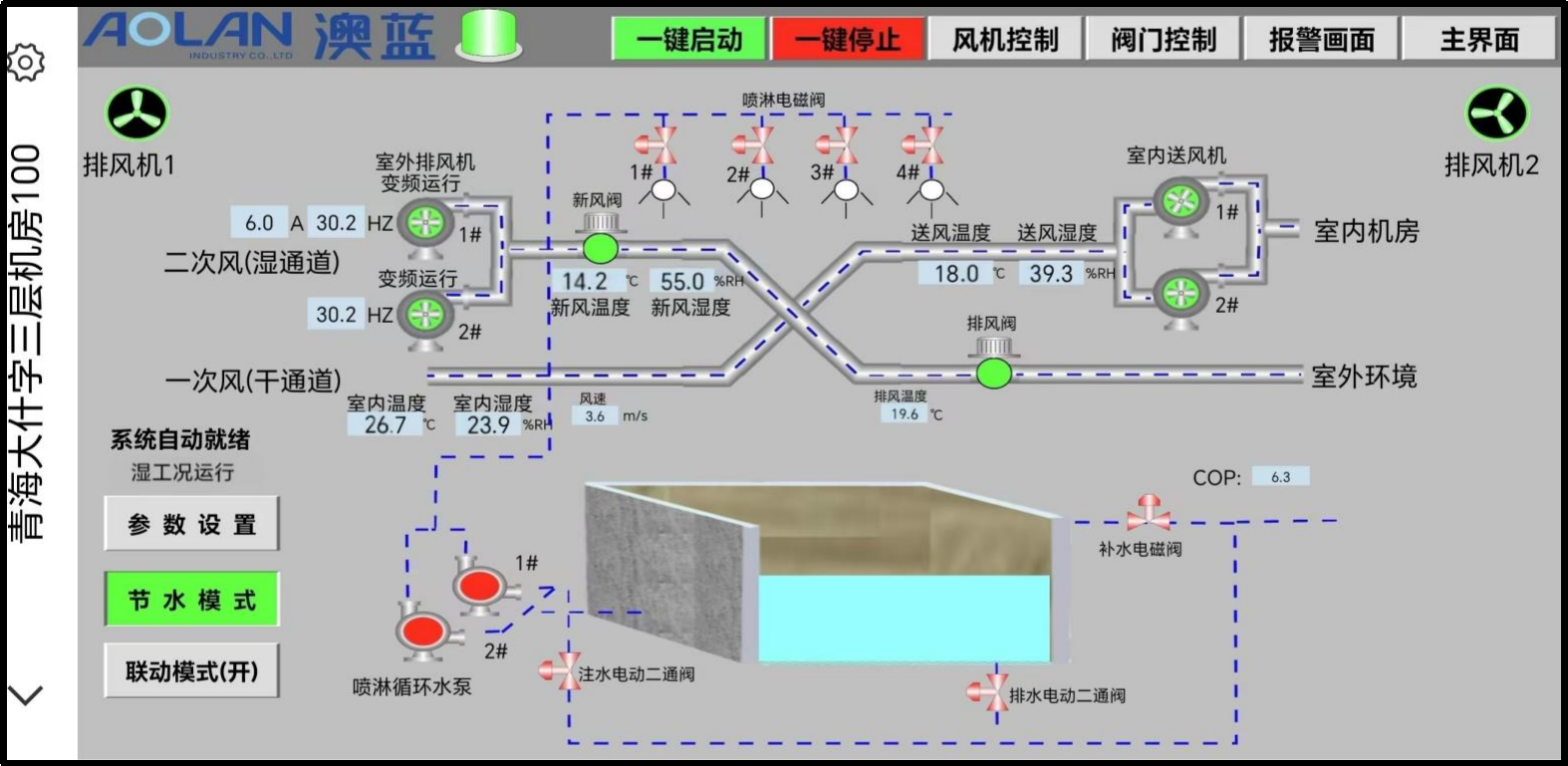

This project underwent on-site acceptance in accordance with the acceptance documents/standards/terms agreed upon by both parties. The acceptance results met the design requirements. Through long-term transportation tracking records, when the outdoor wet bulb temperature is ≤9℃, the air supply of the indirect evaporative cooling air cooler unit The temperature can be maintained at around 19°C without turning on the precision air conditioner in the original computer room. The test results are as follows:

Equipment 1 (60kW): outdoor dry bulb temperature is 14.1℃, wet bulb temperature is 9.1℃, supply air temperature is 18.1℃, relative humidity is 39.1%;

Equipment 2 (100kW): Outdoor dry bulb temperature is 14.2°C, wet bulb temperature is 9.0°C, supply air temperature is 18.0°C, and relative humidity is 39.3%.