Your current location:Home > Project > Liquid Desiccant Air Conditioner

Solution dehumidification unit project of an electronics factory in Yantai

Project Overview

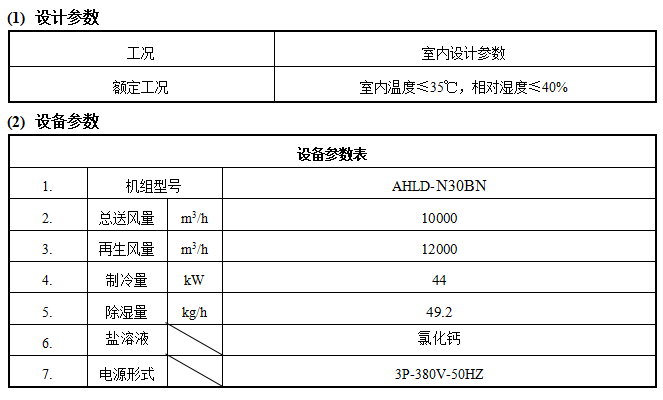

This project is located in Yantai City, Shandong Province and is mainly used for the production workshop of copper and aluminum foil. Aolan solution dehumidification fresh air unit plays a vital role in maintaining the stability of the humidity in the production workshop. The unit can effectively prevent the accumulation of dust and harmful gases, and ensure the ductility and processing performance of materials by accurately controlling temperature and humidity fluctuations. Achieve optimal conditions to ensure the quality of the final product.

Renovation plan

The project is designed to use multiple Aolan counter-flow heat pump solution dehumidification fresh air units. The equipment is arranged in the indoor air-conditioning machine room and roof platform. This project is a deep dehumidification renovation project for the air-conditioning system, which mainly solves the problem of insufficient dehumidification capacity of the original combined air-conditioning supply system in high-temperature and high-humidity weather. According to the actual situation of the project, a recycling model is adopted. The solution dehumidification fresh air unit is installed at the back end of the original fresh air unit. The high-humidity outdoor fresh air is pre-cooled and pre-dehumidified by the original fresh air unit and then enters the solution dehumidification unit for deep dehumidification, resulting in lower humidity fresh air. The air and heat pump solution dehumidification fresh air unit bears the fresh air humidity load and part of the indoor humidity load to maintain the indoor environment with low relative humidity requirements.

Effect display

This project underwent on-site acceptance in accordance with the acceptance documents/standards/terms agreed upon by both parties. The acceptance results met the design requirements. Through long-term transportation tracking records, it can be seen that the system can maintain the indoor dry bulb temperature around 35°C and the relative humidity below 40%. .

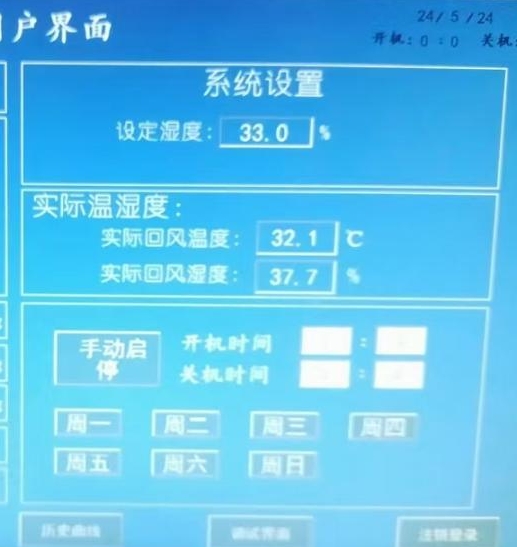

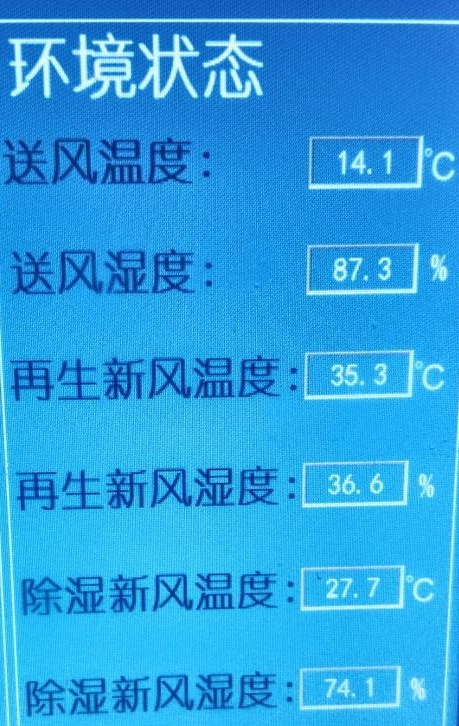

The actual operating conditions are as follows:

(1) Equipment 1: indoor return air, that is, regenerated fresh air temperature, is 34.5°C, and relative humidity is 36.8%;

(2) Equipment 2: The indoor return air, that is, the regenerated fresh air temperature is 35.3°C and the relative humidity is 36.6%;

(3) Equipment 3: The indoor return air, that is, the regenerated fresh air temperature is 32.1°C and the relative humidity is 37.7%;

(4) Equipment 4: The temperature of the indoor return air, that is, the regenerated fresh air, is 30.8°C, and the relative humidity is 38.4%.