Your current location:Home > Project > Liquid Desiccant Air Conditioner

Solution humidity control unit project of an analytical laboratory in Qingdao

Project Overview

The analytical laboratory is located in Qingdao City, Shandong Province, with an area of approximately 680 square meters on the first floor, approximately 1,160 square meters on the second floor, and approximately 1,225 square meters on the third floor, with a floor height of 5.7 meters. The analytical laboratory part of this project adopts a micro-negative pressure design to prevent harmful gases from escaping during experiments, while other non-laboratories maintain a micro-positive pressure to avoid inhalation of dust. Maintain the positive and negative pressure requirements in each room through effective adjustment of fresh air volume and exhaust air volume. The solution humidity-controlled fresh air unit performs humidification treatment on the outdoor fresh air to obtain fresh air that meets the design requirements and sends it to different functional rooms respectively to ensure that the indoor temperature, humidity, and air flow pressure meet the requirements.

Renovation plan

The air conditioning system of this project adopts independent control of temperature and humidity. The variable frequency multi-connected air conditioning system handles the indoor cooling and heating load, and the solution humidity-controlled fresh air unit handles the fresh air and humidity load. In summer, the solution humidification fresh air unit system operates in refrigeration and dehumidification mode to supply dry fresh air indoors; in winter, the solution humidification unit operates in heating and humidification mode to provide humidified fresh air indoors. The laboratory is also equipped with a variable frequency multi-link air conditioner. System indoor unit to maintain indoor temperature stability.

Effect display

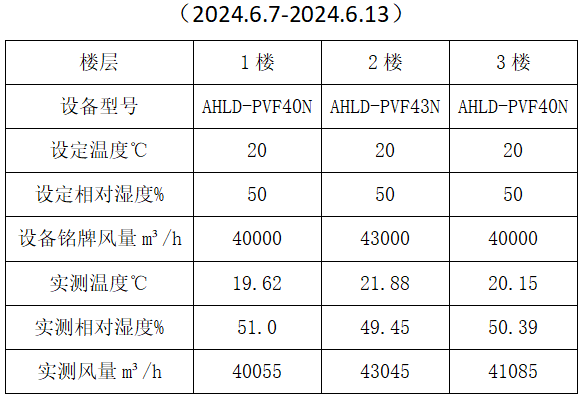

This project underwent on-site acceptance in accordance with the acceptance documents/standards/terms agreed upon by both parties. The acceptance results met the design requirements. Through long-term transportation tracking records, it can be seen that the fluctuation value of the air supply outlet of the unit meets the winter dry bulb temperature of 20℃±1℃, which is relatively Humidity 50%±2%; summer dry bulb temperature 20℃±2℃, relative humidity 50%±3%. The test results are as follows:

(1) Winter:

Equipment 1: temperature 29.9°C, relative humidity 49.7%;

Equipment 2: Temperature 29.6℃, relative humidity 50.2%;

Equipment 3: Temperature 30.3°C, relative humidity 51.9%.

(1) Summer:

Equipment 1: Temperature 19.62℃, relative humidity 51.0%;

Equipment 2: Temperature 21.88℃, relative humidity 49.45%;

Equipment 3: Temperature 20.15℃, relative humidity 50.39%.